Cost-effective CNC machining, prototyping, and production of custom parts.

Your project is unique, and we deliver the service it demands.

Are you looking for a reliable partner to provide CNC machining services?

HKAA Machining is a leading CNC machining services supplier in China.

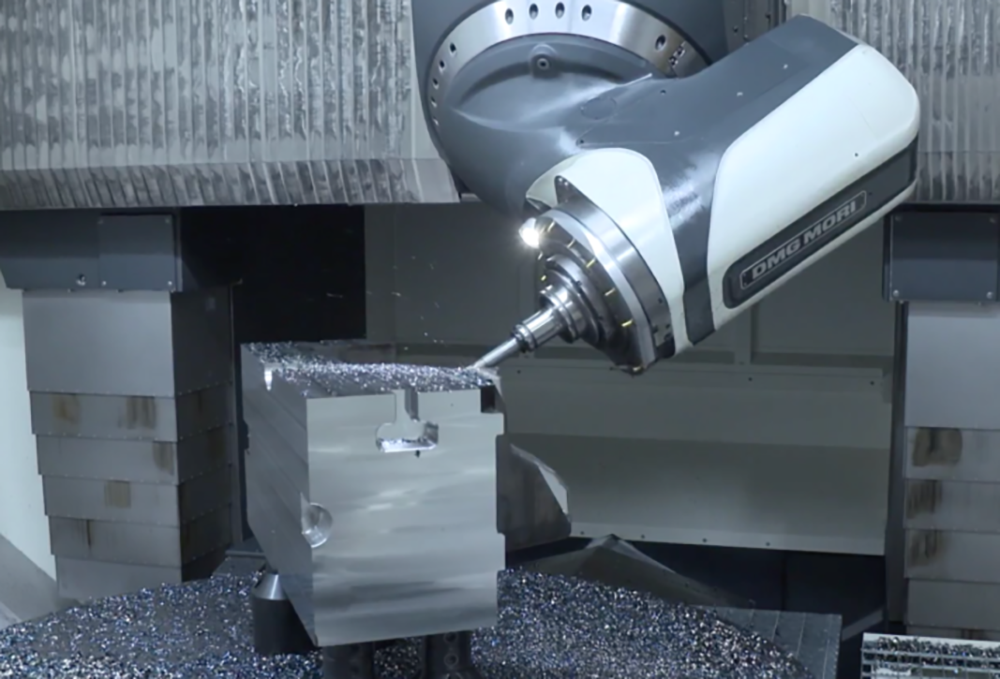

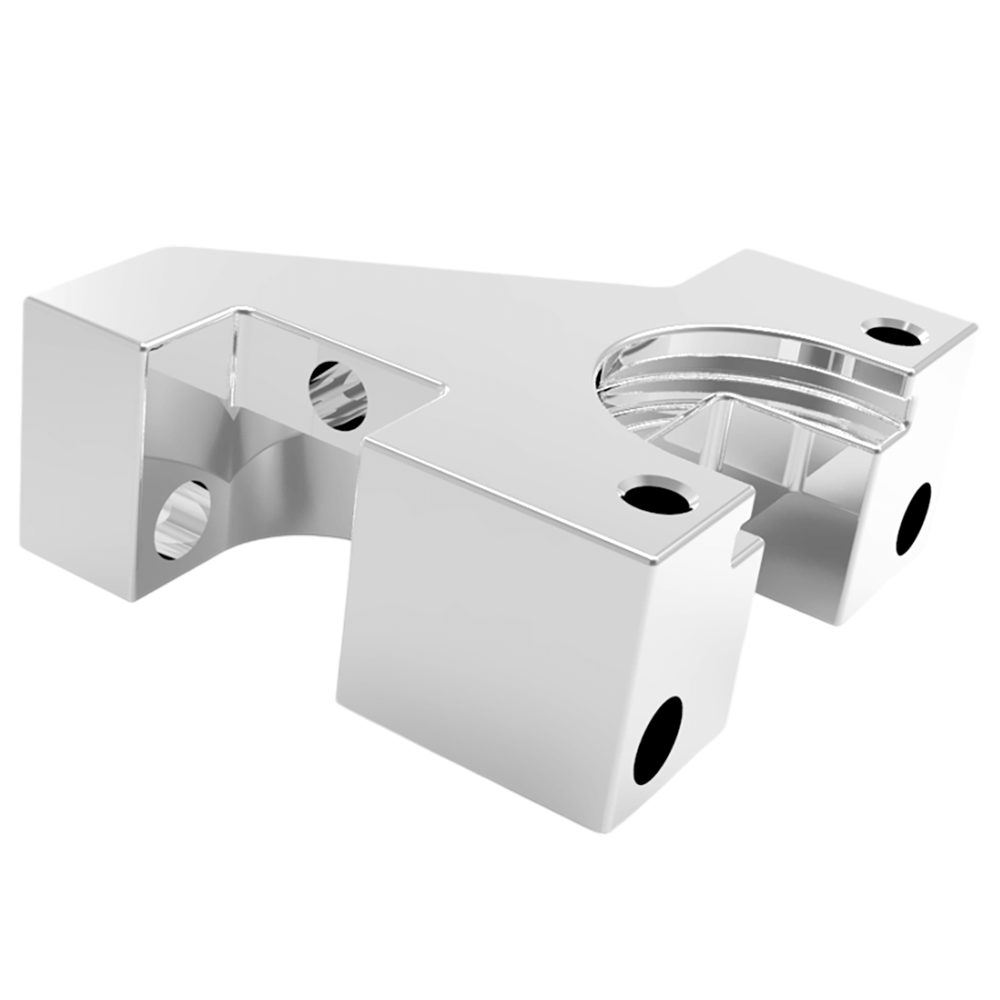

Our 3-axis, 4-axis, and 5-axis CNC milling, turning centers and CNC Lathe machine enable to make precise, high-quality CNC parts that fulfill your custom specifications.

With over 50 sets of CNC machines in China, HKAA Machining can be your ideal choice for outsourcing custom and precision CNC machining services. no matter your industry. Get your quote today.

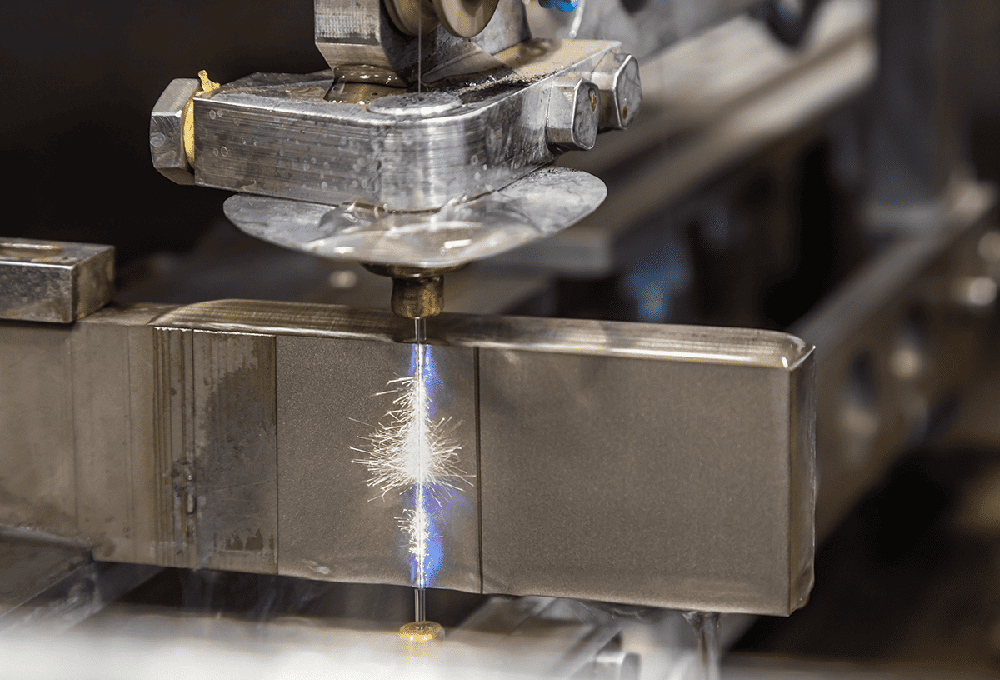

CNC Lathe, CNC Turning, 3 Axis CNC Milling, 5 Axis CNC Machining Service for simple and complex geometrical parts

Precision Wire EDM for Quality Prototypes to High-Volume Production

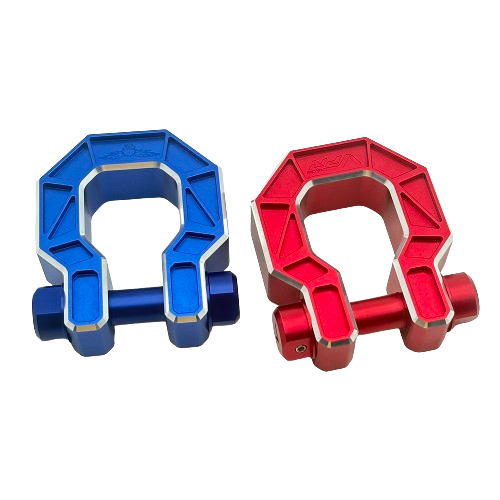

Add multiple finishes to your parts, such as Anodizing, Sand Blast, Powder Coat, Plating, etc

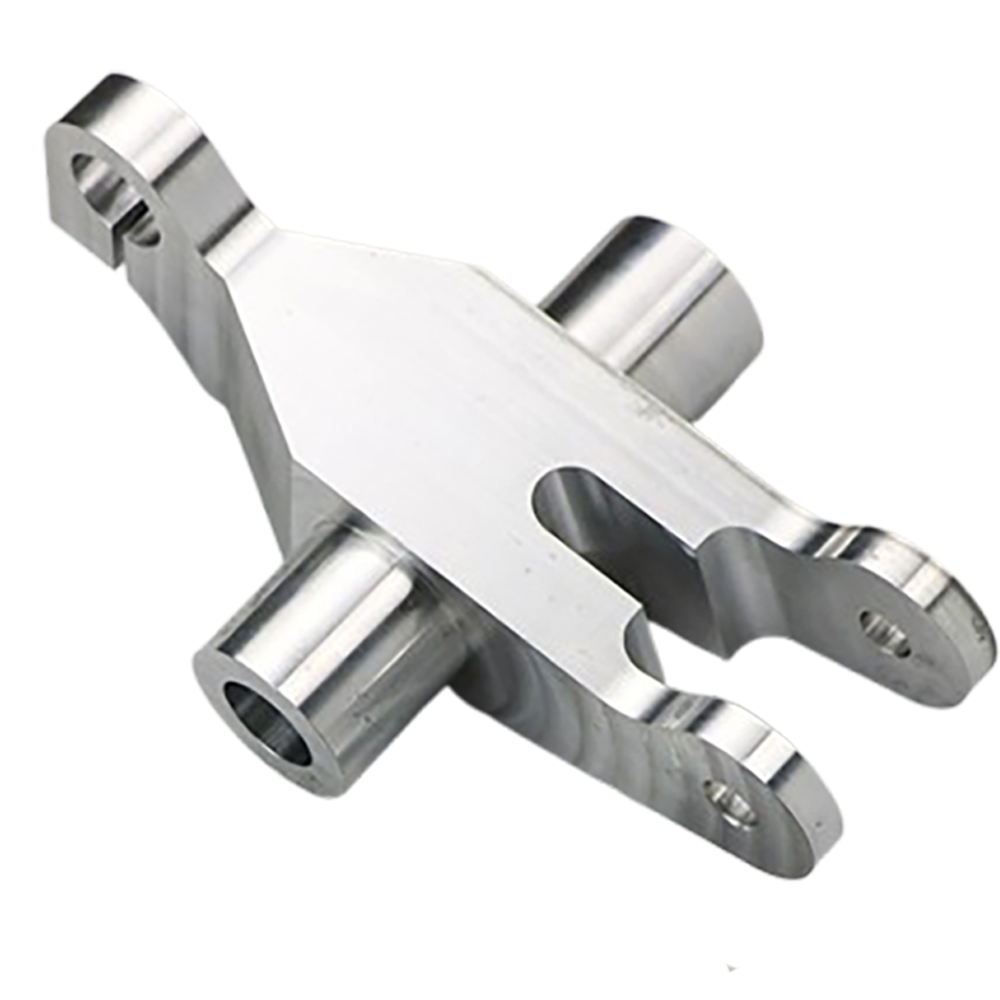

Whether you need a prototype to verify a design or mass manufacturing end products, HKAA Machining has the best solution for you.

Lightweight, corrosion-resistant, highly conductive, versatile in applications.

Superior strength-to-weight ratio, biocompatible, corrosion-resistant.

Dense, malleable, low friction, excellent acoustic properties.

Hard, retains sharpness, abrasion-resistant, ideal for cutting tools.

Rust-resistant, strong, hygienic, widely used in industry.

Great wear resistance, inexpensive, good for heavy-duty parts.

Exceptionally conductive, malleable, antimicrobial, aesthetically appealing.

Resistant to seawater, historic significance, strong, bearings manufacturing.

Tough, high tensile strength, foundational in construction.

Extremely light, decently strong, flammable as powder or ribbon.

With 26 years of machining expertise under our belt, we’ve catered to a broad spectrum of sectors including medical, robotics, consumer goods, automotive, aerospace, defense, marine, green energy, and industrial, among others.

Our deep understanding of our clients’ diverse applications, industry norms, and unique requirements across these fields is what truly sets us apart and adds value for our customers!

“better technology, better quality, better service and better price” to meet diverse needs of customers.

We have long term business relationship with world famous company,like Parker, Ford,HP, HAAS, Schneider,Johnson Controls

We are one of the largest OEM,manufacturer in China with 25 years,experiences in comprehensive,hardware manufacturing including,CNC machining, lathe turning, gear,hobbing, mechanical assembly.

At HKAA Precision Machining, we offer a comprehensive range of CNC machining services tailored to meet the diverse needs of our clients worldwide.

Utilizing cutting-edge CNC technology, we specialize in precision machining that adheres to the highest industry standards

Need a prototype to test your design? Our skilled team can turn your concepts into tangible prototypes, allowing you to assess and refine your ideas before full-scale production.

Our commitment to quality extends beyond production. Rigorous quality control processes are integrated into every step, ensuring that each product meets or exceeds your expectations.

Whether you require complex components or custom parts with intricate designs, we have the expertise to deliver tailor-made solutions that match your specifications.

Choosing the right materials is crucial. Benefit from our industry knowledge as we guide you in selecting materials that align with your project requirements and budget.

Partner with our experienced design team to optimize your designs for manufacturability. We believe in collaboration to achieve the best results for your projects.

Time is of the essence? Our rapid prototyping service accelerates the development process, allowing you to quickly iterate and move from concept to production in record time.

Our customer support team is here for you. From project inception to delivery, we provide responsive and personalized assistance, ensuring a smooth and satisfying experience.

Accuracy and precision: CNC machines are highly accurate and can consistently produce parts with tight tolerances. This level of precision is difficult to achieve with manual machining processes.

Repeatability: CNC machines can produce identical parts over and over again with the same high level of accuracy and precision. This makes CNC machining ideal for large-scale production runs.

Speed: CNC machines can produce parts quickly and efficiently, especially when compared to manual machining processes. This allows for faster turnaround times and shorter production cycles.

Flexibility: CNC machines can be programmed to produce a wide range of parts and can handle a variety of materials, including metals, plastics, and composites.

Reduced labor costs: Because CNC machines are automated, they require less human intervention than manual machines. This means that fewer workers are needed to operate and monitor the machines, which can result in lower labor costs.

Complexity: The programming and operation of CNC machines require specialized training and technical knowledge. This can be a challenge for companies that don’t have experienced CNC operators on staff.

Limited flexibility: While CNC machines can produce a wide range of parts, they are limited by the size and capabilities of the machine. This means that some parts may be too large or too complex to be produced by a particular CNC machine.

Material limitations: While CNC machines can handle a wide range of materials, certain materials may be more difficult to machine than others. This can result in longer machining times, increased tool wear, and other challenges.