HKAA Machining offers premium anodizing services to enhance durability and aesthetics of aluminum components. Our advanced techniques ensure precision finishing that meets diverse project needs.

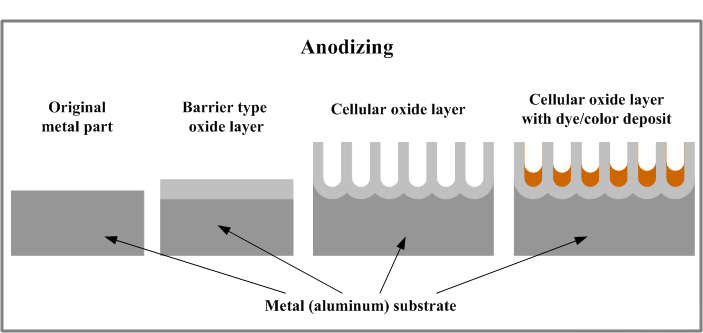

Anodized aluminum is aluminum that has been subjected to an electrochemical process called anodization, creating a protective oxide layer on its surface. This layer makes it more resilient to corrosion and can also accept custom surface coloration.

The main goal of aluminum anodization is to change the metal’s surface chemistry. It simultaneously creates a barrier against corrosion, enhances aesthetics, and increases scratch resistance via a very tough and transparent anodic finish.

The anodization process is significant because it can improve important qualities like wear resistance, corrosion resistance, surface lubricity, heat dissipation, dielectric characteristics, adhesion, and aesthetics. These improvements make it essential in some sectors.

Anodizing creates a thick oxide layer on the aluminum surface. This layer, being much harder than the aluminum itself, offers enhanced protection against chipping, peeling, and scratching, ensuring the component's longevity.

The protective oxide layer formed during the anodizing process acts as a barrier against environmental factors such as moisture, salts, or other corrosive agents. This protection ensures that aluminum parts remain unaffected by rust or corrosion, especially in challenging conditions.

Anodized aluminum surfaces can be dyed in a variety of colors. This flexibility in design choices, coupled with a rich metallic sheen, often results in a more attractive appearance than untreated or painted surfaces.

The oxide layer that results from anodizing acts as an insulator. This insulation property can be crucial in electronic applications where specific components must be electrically non-conductive to function correctly.

Certain types of anodizing can enhance the aluminum's thermal insulation properties, making it ideal for applications where heat retention or dissipation is a factor.

Certain types of anodizing, like Teflon-impregnated hardcoat anodizing, can improve the lubrication properties of aluminum parts, reducing friction in moving components.

The main goal of aluminum anodization is to change the metal’s surface chemistry. It simultaneously creates a barrier against corrosion, enhances aesthetics, and increases scratch resistance via a very tough and transparent anodic finish.

At HKAA Precision Machining, we offer a comprehensive range of CNC machining services tailored to meet the diverse needs of our clients worldwide.

Utilizing cutting-edge CNC technology, we specialize in precision machining that adheres to the highest industry standards

Need a prototype to test your design? Our skilled team can turn your concepts into tangible prototypes, allowing you to assess and refine your ideas before full-scale production.

Our commitment to quality extends beyond production. Rigorous quality control processes are integrated into every step, ensuring that each product meets or exceeds your expectations.

Whether you require complex components or custom parts with intricate designs, we have the expertise to deliver tailor-made solutions that match your specifications.

Choosing the right materials is crucial. Benefit from our industry knowledge as we guide you in selecting materials that align with your project requirements and budget.

Partner with our experienced design team to optimize your designs for manufacturability. We believe in collaboration to achieve the best results for your projects.

Rust Our One-Stop Finishing Excellence

HKAA-Machining’s industry-leading expertise ensures unrivaled quality and convenience with our comprehensive, one-stop finishing services

Powder coating is a dry finishing process, using finely ground particles of pigment and resin electrostatically charged and sprayed onto surfaces. Cured under heat, it creates a durable, uniform, and attractive finish, popular for its environmental and performance benefits.

Black oxide, a conversion coating in surface finishing, chemically forms a protective black layer on metals, primarily ferrous alloys. It enhances corrosion resistance, reduces light reflection, and adds decorative appeal. Applied through hot or cold processes, the finish is often sealed with wax or oil to boost durability and protection.

Chromate conversion coating, often known as Alodine or Chemfilm, is a surface treatment for aluminum and its alloys. It forms a thin, protective chromate layer, enhancing corrosion resistance, promoting paint adhesion, and providing electrical conductivity. Commonly used in aerospace and automotive industries, it offers a decorative finish with minimal dimensional change.

DLC (Diamond-Like Carbon) coating is a nanocomposite finish that imparts a hard, wear-resistant surface to materials. Mimicking properties of natural diamond, it offers exceptional lubricity, corrosion resistance, and a reduced friction coefficient, making it ideal for automotive, tools, and precision components.

Brushing in surface finishing uses abrasive brushes to create fine, consistent lines on metal surfaces. This mechanical process enhances appearance, masks defects, and prepares surfaces for coatings. Offering various textures, from short to long grains, brushing ensures aesthetic refinement for various applications.

Titanium anodizing is a surface finishing process that modifies the oxide layer on titanium components. Enhancing corrosion resistance and biocompatibility, it also adds vibrant, interference-based colors without dyes or pigments. Popular in medical devices and aerospace, it combines aesthetics with functional benefits.

Passivation is a surface finishing process that treats stainless steel with a mild oxidant, removing iron contaminants and enhancing its natural oxide layer. This strengthens corrosion resistance and prevents unwanted reactions in environments like the medical, food, and aerospace industries.