HKAA Machining excels in automotive prototyping, delivering exceptional precision in auto parts manufacturing. Specializing in crafting high-quality mechanical components, our expertise ensures top-tier results in every project.

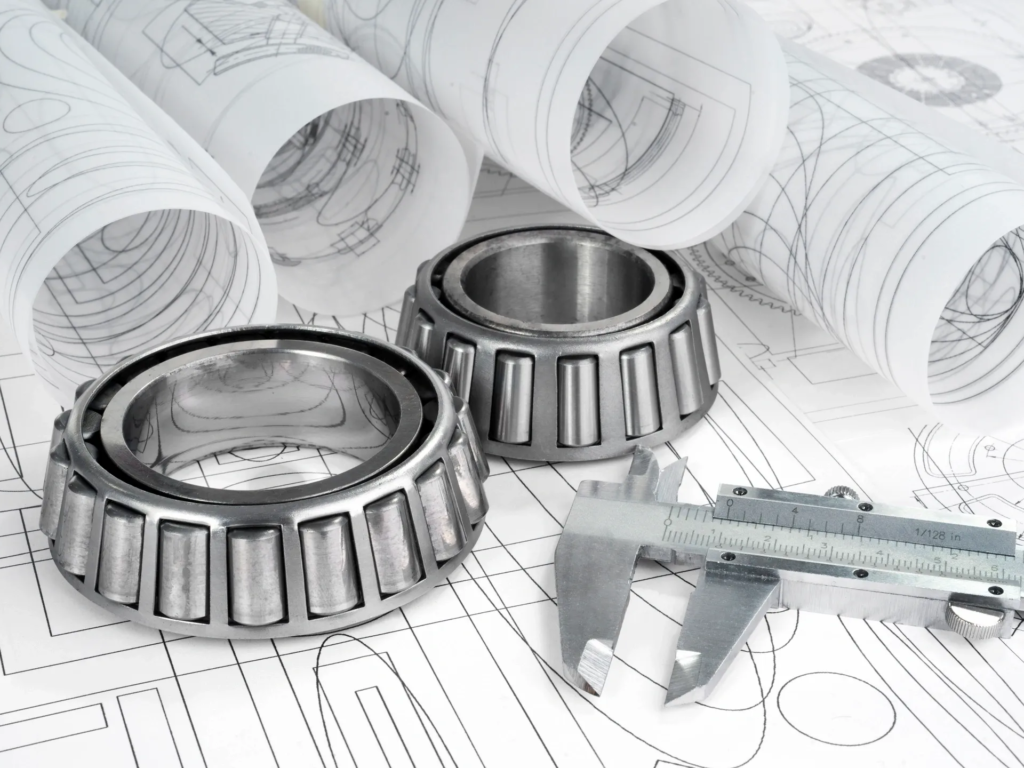

At HKAA, we offer different CNC machining services and capabilities for manufacturing CNC auto parts. We use 3-, 4-, and 5-axis CNC machining for production. We are also well-equipped with 400 sets of CNC precision machines and equipment.

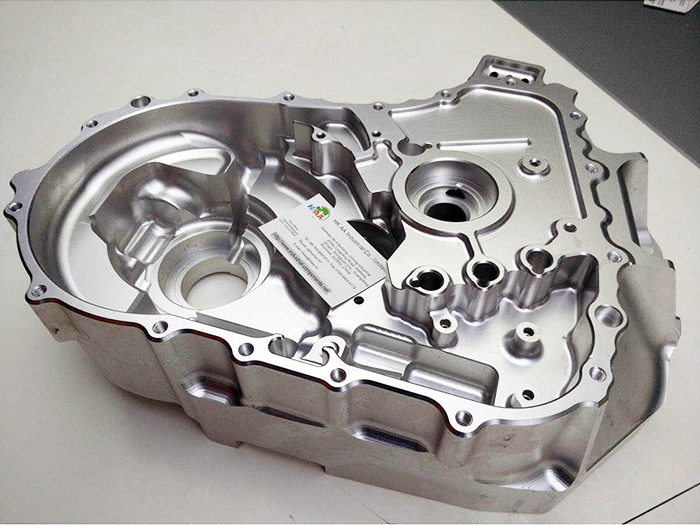

Among the CNC auto parts, we produce include drive axles, gearboxes, starter motors, cylinder heads, and more. We guarantee that all these parts are manufactured with tight tolerances up to +/-0.02mm.

Here in HKAA, we can provide single-run prototypes to large volume CNC auto parts production. We guarantee quality and precision when manufacturing CNC car parts.

With HKAA-Machining‘s expertise in automotive prototyping and auto parts manufacturing, we ensure quality and precision. Discover the process that aligns with your product requirements, and enhance your production experience with us.

HKAA Machining expertly crafts precise, functional automotive mechanical prototypes using CNC machining, silicone molding, and rapid tooling. This precision approach provides accurate performance feedback and data in challenging tests, crucial for design validation and refinement.

HKAA Machining aids in creating custom car parts for unique prototype designs using advanced techniques like CNC Machining and Vacuum Casting. These methods allow for high precision and versatility in producing components that meet specific design requirements, ensuring a perfect fit and function for your custom automotive prototypes.

CNC Machining offers detailed and accurate fabrication, while Vacuum Casting is ideal for replicating parts with consistent quality, making HKAA-Machining a reliable partner for custom automotive prototyping needs.

We focus on automobile, motorcycle, motorboat, bicycle, ATV, kart, truck, boat, modified car accessories. We have many production experiences in engine accessories. Welcome to provide drawings or samples for customization.

CNC machining auto parts offers fast speed production whether medium or high production volume. Since CNC machining is an automated process, labor-intensive and lengthy manual machining are eliminated. Thus, speeding up and optimizing the production process.

The same auto parts can be manufactured multiple times by using CNC machining. Thus, large volume production of a single auto part is possible. CNC machining auto parts large volume production is more cost-effective.

Most CNC auto parts are manufactured with +/-0.001 tolerances. Thus, you can assure high accuracy and precision. Rest assured that all HM CNC auto parts can meet the highest demands of the automotive industry.

CNC auto parts can be manufactured according to the customer’s request. From sizes, designs, whether simple or complex, HM can customize for you. Just send us your details or drawings. Our engineers will cater to your needs to meet your requirements.

The procedure begins with the creation of a computer-aided design.It is essentially a code that is fed into CNC machines.They begin working and manufacturing parts after this code is installed.The code includes drill, mill, and turn instructions for the raw material.This code is used by CNC machines to run the production process as a set of orders.This series of machine instructions provides the automation present.Following that, the machines continue to work, transforming the raw resources into the necessary CNC car part.It accomplishes this by removing material from specific locations.

In recent years, CNC auto parts for the automotive industry have grown popular.

Some of the benefits of CNC auto parts are as follows:

It provides faster production times than traditional machining for moderate to high production rates. Some steps help to accelerate and optimize the machine’s run time.

It also simplifies the automotive manufacturing process. As a result, employees will devote more time to tasks involving design and innovation.

It ensures repeatability because it is a computer-controlled process. It is critical in the automotive sector to ensure that sections are accurate from different batches.

It can achieve dimensional accuracy for parts that require them. It can reach the necessary safety margins for the motor and other functional parts.

When producing large quantities of items, CNC auto parts are used. Automakers can meet ever-increasing production and market demands while also saving resources.

It aids the automotive industry in the production of customized parts. This benefit is derived from short lead times, whether as one-offs or limited production volumes.

It handles all manufacturing processes for a modernized outcome so that personnel will focus on innovation and layout.

Keep in mind how long you want the machine and spare parts will last. CNC auto parts are manufactured to order and are a durable option.

It gives the correct requirements, which increase the likelihood of compatibility. Higher compatibility, in the end, extends the lifespan of your machinery.

Aside from its numerous applications, CNC machining also aids in the production of multiple auto parts for cars.

Among these are:

Other CNC Auto Parts:

Different parts necessitate various materials, such as metal and plastic.

Here are the commonly used materials:

CNC auto parts are helpful in the automotive sector for prototyping and production.

The process benefits from providing high-quality, functional parts in the latter case.

Before going into production, prototypes are tested and validated.

The system is applicable for many vehicle parts due to the wide range of materials compatible with CNC Machining.

You can also use CNC auto parts to display interior design features.

Using this together with explicit acrylic materials, for example, rapid prototyping of lighting parts is simple.

It can also generate massive functional parts for testing performed during new car models.

CNC auto parts have a wide range of options for personalization services for numerous companies worldwide.

It will surely save time and money while offering high-quality CNC auto parts that will last a lifetime.

CNC auto parts are built and designed to your requirements and it is made of the current industry technologies.

The following finishing processes have been used to make CNC auto parts:

The coating process and grade used to obtain outcomes and requirements vary based on what parts will be used for.

CNC auto parts have a wide variety of features such as the following: