China high-quality precision CNC milling services you can trust. Competitive pricing and fast lead times.

CNC Milling is a subtractive manufacturing process that uses computer-controlled machines to remove material from a block (known as a blank or workpiece) and shape it into a finished part. The process begins with a CAD model, which is then converted into a CNC program and set up in the CNC machine.

CNC stands for Computer Numerical Control milling. This means that the milling machine is moved and monitored by numerical computer control rather than by hand. CNC milling tools perform a machining process similar to drilling and cutting parts with incredible precision, leaving no room for human error.

HKAA Machining is the premier supplier of CNC-milled parts. Our experienced engineers, designers, and procurement units ensure that our services are provided efficiently and cost-effectively for all project needs ranging from prototypes to mass production runs.

All this, backed by high-tech milling centers with a wide range of finishing options, allows us to deliver top-notch quality quickly, reliably, and flexibly – perfect for your precision manufacturing requirements!

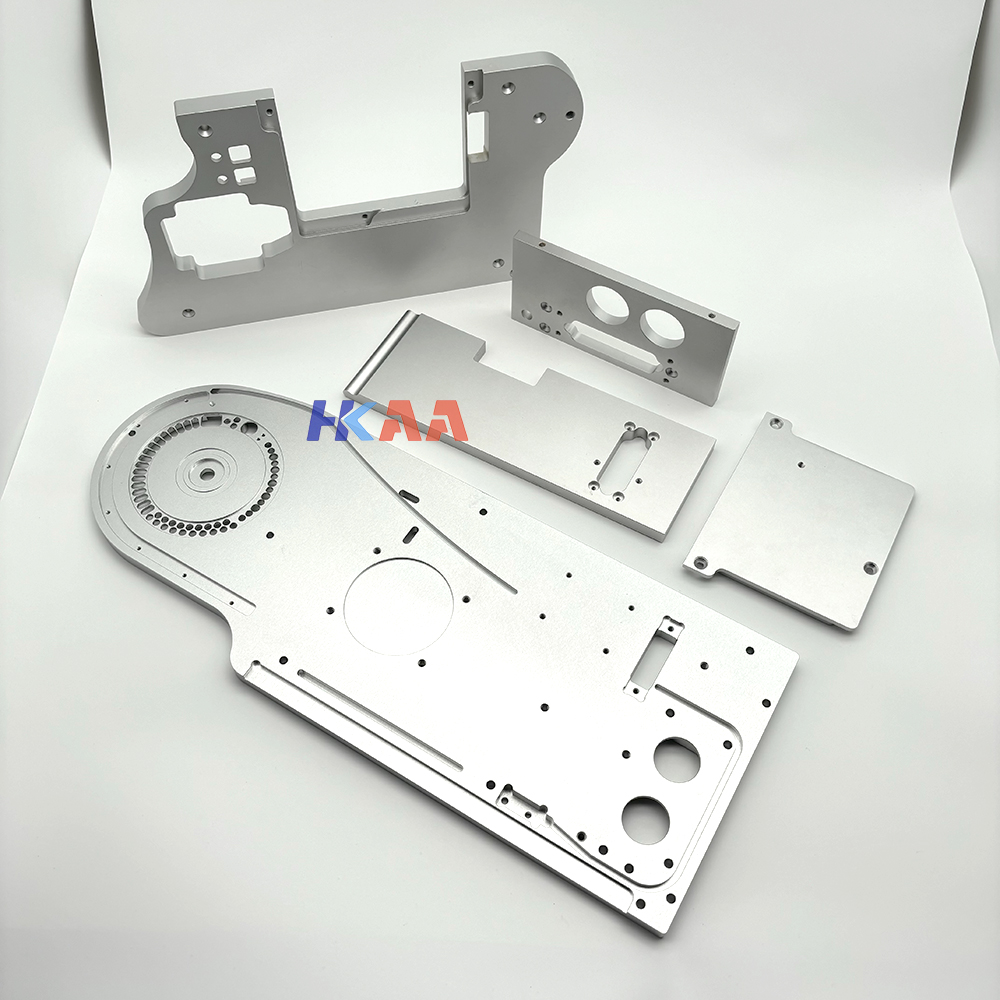

CNC Milling Products

Your Global Partner for Quality CNC Machining Services

Time-sensitive projects excel here, as we offer swift production turnarounds without compromising the integrity or quality of our CNC machined parts.

HKAA already gained more than 10 patent sand passed certifications such as AS9100 for aviation industry,ATF16949 for automobile industry,IS013485 for medical device industry.

HKAA Machining commitment to meticulous accuracy delivers parts that consistently meet the strictest specifications, ensuring your projects are executed flawlessly.

Drawing from our expertise, we'll scrutinize your part's manufacturability, advising on materials and design optimizations to provide cost-reduction strategies tailored to your needs.

HKAA offers a wide variety of materials for custom CNC machining, plastic, and metal, including but not limited to:

HKAA Machining offers a wide selection of surface finishes to improve the surface qualities of CNC-turned parts. The surface finishes applied after machining can change the appearance, surface roughness, hardness, and chemical resistance of the produced parts.

This finishing option with the shortest turnaround time. Parts have visible tool marks and potentially sharp edges and burrs, which can be removed upon request.

Smooth machining is similar to a ‘As machined’ finish, but with less visible machine marks. Parts are machined at a lower feed rate, with no hand polishing.

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment.

Machined parts are bead blasted with glass beads which results in a uniform grainy texture and reduced machining marks.

It is a process that tumbles vibrating media on machined parts to remove sharp edges and burrs. Tumbling can be used to remove machine marks from exterior surfaces.

The parts are bead blasted to #120 grit before being anodized type II—ideal for increasing the aluminum part’s corrosion resistance and cosmetic effects.

The parts are bead blasted to #120 grit before being anodized type III. Type III (Hard Coat) is thicker and adds a wear-resistant layer to Type II’s corrosion resistance, suitable for functional applications.

Black oxide is a conversion coating that is used on steels to improve corrosion resistance and minimize light reflection.

end in your CNC Milled parts order today and experience a painless, streamlined process that will get you quality results with a fast turnaround.

We offer high-quality finishing processes for most CNC Milled parts, including anodizing, polishing and plating, heat treatment, powder coating, DLC coating, and more.

Our team guarantees exceptional after-sales service and solutions and takes full responsibility in resolving any potential issues. We never turn a blind eye, but proactively tackle challenges head-on to ensure our customers are satisfied.

By incorporating state-of-the-art milling machines, streamlining our production processes, and buying our raw materials in bulk quantities, we're able to minimize your expenses by anywhere from 30% to 60%.

We offer over 60 production grade materials, and take great care to ensure the right material is used for every part.

Our standard CNC tolerance is +/- 0.127mm, and when you use our tolerance configurator, you can expect precision machining to +/- 0.005mm.