HKAA-Machining offers a diverse range of plastic for CNC machining, with applications in a variety of industries. Ideal for one-off prototypes as well as end-use custom parts.

Choosing the proper plastic for CNC machining involves considering some factors. The plastic you select is critical to the final success. For example, the plastic may need to be resistant to high temperatures or bend or break under pressure. When choosing the correct plastic, corrosion resistance, workability, pricing, weight, and visual look all play a role.

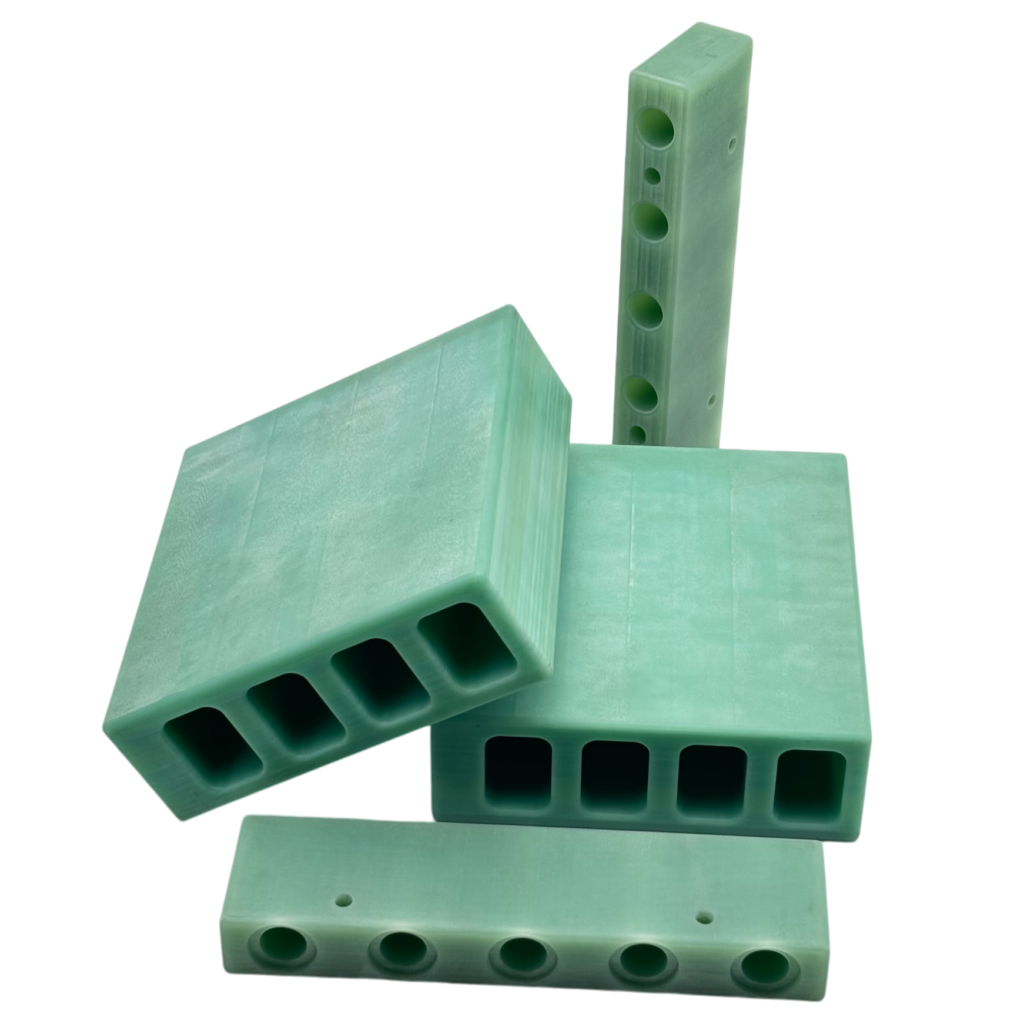

High strength, stiffness; low friction; excellent dimensional stability.

Good chemical resistance; easy to weld and machine; durable.

Tough, impact-resistant; easy to machine; popular for prototyping.

Optically transparent; UV resistant; good weatherability; brittle.

Wear-resistant, strong; good sliding properties; absorbs moisture.

High strength and heat resistance; flame retardant; medical-grade.

High-temperature resistance; superior mechanical properties; chemical resistant.

Exceptional thermal and chemical stability; high strength and stiffness.

Extremely low friction; high heat resistance; chemically inert

Excellent impact resistance; low moisture absorption; chemical resistant.

Plastic CNC machining is a subtractive manufacturing process that involves placing a solid block of plastic material against a mobile cutting tool to remove materials from it. A digital design file guides the path of cutting tools, ensuring the final product takes the desired shape.

CNC plastic machining is the current manufacturing trend in making plastic components and parts. This is due to the ability of this process to create parts with uniform, high precision, and tight tolerances.

There are several reasons why plastic manufacturers choose CNC plastic machining over other forms of plastic manufacture. Here are some advantages of plastic CNC machining

One of the main advantages of plastic CNC machining is its ability to create parts without molds, making it ideal for prototypes and short-run production. Unlike injection molding, CNC machining does not require the expensive creation of metal tooling, which helps reduce production time and costs.

Plastic CNC machining is an ideal solution for parts requiring high-precision measurements, as it offers superior levels of accuracy and repeatability compared to injection molding and 3D printing processes. This makes it perfect for applications in high-precision industries where exact tolerances must be met.

The excellent structural properties of engineering-grade CNC machined plastics, including electrical insulation and strength-to-weight ratio, make them ideal for plastic machining. Thus, with plastic machining, machinists can use a wider range of materials for plastic fabrication, with popular ones including HDPE, ABS, Nylon, Acrylic, Delrin, PEEK, and so on.

CNC machining is a popular method for fabricating high-precision plastic parts used in the medical industry, such as medicine dispenser components, handles for surgical tools, and components for medical devices. There are many medical-grade materials available for CNC machining.

CNC-machined plastics are ideal for producing parts used in the food and beverage industry, such as valves, nozzles, and seals. These parts are used in food processing and packaging machines.

The semiconductor industry relies on plastic CNC machining to create precise parts from high-performance engineering plastics. These intricate parts require extremely tight tolerances and good surface finishes that would not be possible without the precision of plastic CNC machining.

Plastic CNC machining is one of the best ways to manufacture high-performance CNC-machined plastic components for use in the aerospace and automotive industries. The reason is that plastic machining can fabricate most plastic materials that meet the strict regulations and requirements needed by these industries.

Are you looking for complete solutions to producing plastic parts with tight tolerances and surface finish?

HKAA Machining offers a state-of-the-art CNC Machining service, guaranteed quality, and fast lead time. With over 50 plastic milling and plastic turning machines, we can provide consistent, high-quality machined parts and competitive price.

So, with us, you can make easy or complex orders for prototypes, low to large volume CNC production runs in a wide variety of plastic.

Plastic CNC machining is a process of using computer numerical control (CNC) machines to shape and cut the plastic material into the desired shape. This technique is highly accurate, allowing for the production of complex designs with intricate detail or complex geometries.

The cost of plastic CNC machining depends on many factors, including the material used and the expertise of the machining services provider or CNC milling machine shop. However, the cost could be as low as $10 per hour.

The best plastics for machining include; Acetal, PEEK, and PVC. The reason is that they have a high degree of machinability and offer good dimensional stability.

Also, these different plastics are readily available at a low cost and have the potential to resist chipping and melting. They are also impact-resistant and have high impact strength.